Precision in Every Drop

A net weight filling machine will also be essential in industries where the measurement accuracy of filling =cost control and product quality. Net weight filling is different as it measures the weight of the product actually being dispensed rather than filling up to a set volume - which could be influenced by factors like temperature and viscosity. This method is proven to be accurate within + / - 2% to the gram (0.001lb or 0.01lb scales, exceptional designs the min weight is covered and the cal medication mass is calculated based on the size to achieve the desired precision.) across every fill pack-out. This level of precision is often necessary in industries that make chemicals, pharmaceuticals or food products to comply with regulations and please their customers. For example, a standard net weight filler provides its fill weight accuracy to within 0.1% what the pour weight will be making it critical in quality control.

Improved Production Efficiency

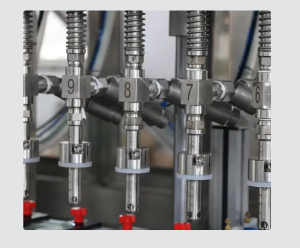

A net weight filling machine is the sake of experience where it can provide several time more efficient to the production. With automatic fill nozzle control, these machines are well equipped to fill up the common bottles at high speeds while making changes across different sizes without needing manual labor. With their ability to accommodate different container sizes - from small bottles to large drums - they can process up to 20 containers per minute depending on the sophistication of the system and the container size. With this level of efficiency, production lines are able to maintain their pace and accuracy in each fill.

Sustainable Cost Reduction through Waste Minimization

Reduced wastes - A Net weight filling machine offers a host of benefits but one of the most recognized amongst the enterprises is an appreciable reduction in product wastages. Since the machines only dispense the required amount of product, this significantly reduces overfilling-a common problem with less accurate filling techniques. So unique cutting provides you with a way to save on the raw products that would otherwise have been wasted as well as part of the costs that may arise from excessive product give-away. The savings in product costs from less waste will eventually pay for the filling machine, if utilized long enough.

Professional Compliance

In most regulated industries, product counts are common customer satisfaction problem, but also a legal compliance issue. Weight filling machines net weight filling solutions can guarantee that the weight of the product in each container meets the labels, preventing any fines from the regulatory agencies. This is even more crucial when it comes to industries like pharmaceuticals, where incorrect product quantities can be dangerous for health.

Modular and scalable offerings

Net weight fillers are recognized for their versatile nature. It is fully scalable to high volume and fits seamlessly into current production lines with minimal changes. No matter if your operation needs to fill 100 or 10,000 containers a day, a net weight filling machine can be easily tuned to do so just as efficiently and accurately.

Looking Forward

Introducing a net weight filler is more than just an increase in production output; it is a calculated next step for your business that improves accuracy of fill, production speed, and compliance. These machines measured in single microns, and judged their adaptability to the demands of batch layout, so they are a necessity for making money and containing the tolerance of industry.